1

Celle fotovoltaiche controllate e selezionate

La fasi di produzione

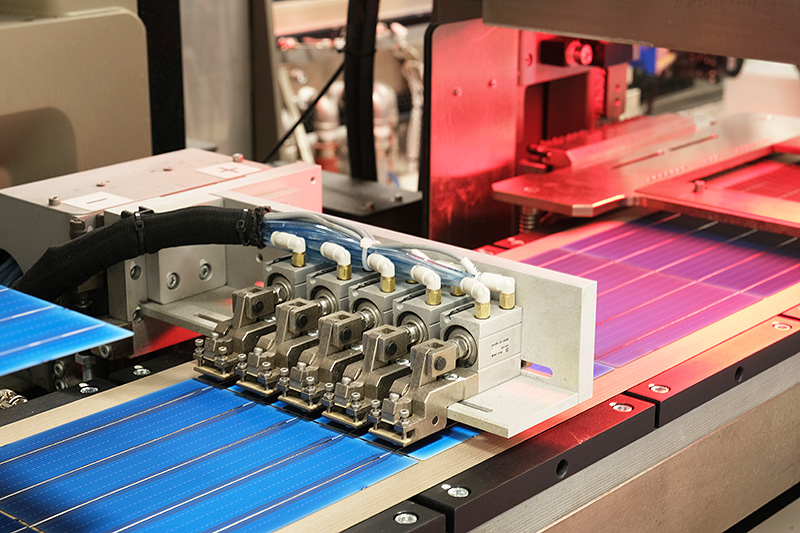

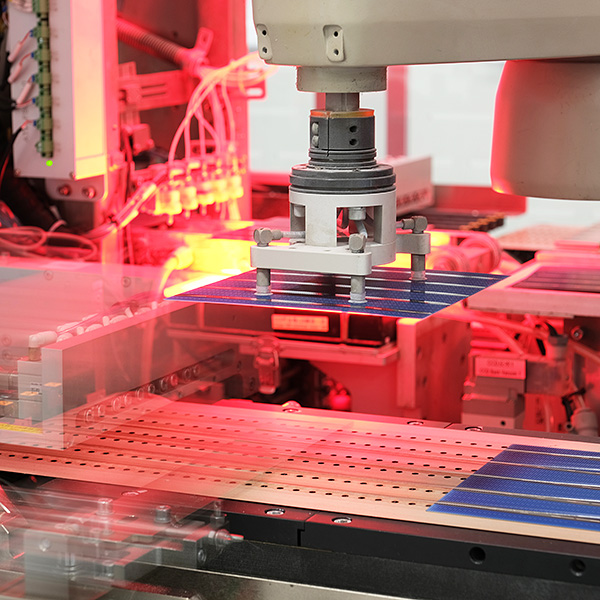

Il ciclo produttivo dei nostri moduli fotovoltaici si compone di diverse fasi, tutte seguite da tecnici specializzati e finalizzate alla produzione di moduli fotovoltaici ad alta resa. Le aree produttive sono tutte mantenute a temperatura ad umidità controllate, al fine di garantire la perfetta conservazione dei materiali prima della laminazione.

2

Lavorazioni

Saldatura e laminazione

A seguito del carico del vetro e del deposito del primo foglio di EVA in modo completamente automatico, le stringatrici uniscono con precisione millesimale le celle e preparano le stringhe, che verranno depositate delicatamente da un robot antropomorfo per essere collegate tra loro. Completata questa fase e posizionati il secondo foglio di EVA e il backsheet sul retro del prelaminato, il pannello verrà in modo automatico trasportato fino al laminatore che, estraendo l’aria ed effettuando il ciclo di laminazione ad alta temperatura, completerà questa prima importante fase produttiva per la composizione del sandwich.

3

Ultimi passi per la conclusione del ciclo

Rifilatura, incorniciatura e test elettrici

Un volta rifilato in automatico, il laminato viene incorniciato con specifici profili di alluminio anodizzato.

Assemblata anche la scatola di giunzione, i moduli oramai terminati verranno testati al 100% con moderni e certificati macchinari (prova di continuità, simulazione solare ed elettroluminescenza).

4

Fase conclusiva

Etichettatura

Questa fase è importante per identificare ogni singolo modulo in modo univoco, riportando il numero seriale già inserito all’interno del sandwich e tutti i dati rilevati dal simulatore solare, classe di appartenenza inclusa.

Anche l’imballaggio, eseguito con particolare cura, riporterà i numeri seriali dei moduli contenuti permettendo così la completa tracciabilità del prodotto dall’inizio alla fine del processo produttivo.

Eclipse Italia, produttori di pannelli fotovoltaici

Qualità italiana